Products

Target

Sputtering Target

- We provide metal oxide semiconductors such as IGZO (InGaZnOx) which are used for TFT purposes and high-quality transparent conductive film materials (TCO) such as WIDE BAND GAP materials and RRAM materials.

SPECS

◇ What is a sputtering target?

Thin films with distinctive functions are used in the products around us, such as displays such as smartphones and LCD TVs, energy such as solar cells and lithium batteries, and recording media such as DVDs and hard disks.

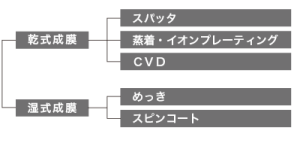

In order to make such a thin film, applications such as sputtering, vapor deposition, ion plating, CVD (vapor phase growth method), which is a dry (vacuum) film forming method, and plating, spin coating, which is a wet film forming method, etc. Various processes have been developed by.

Among them, sputtering is a method that can form a uniform film over a large area, and is the mainstream for thin film production not only in the research and development field but also in mass production in factories. The general spattering procedure is as follows.

(1) Place the film-forming material (metal, alloy, oxide, etc.) on one side of the vacuum chamber and the substrate on the other side.

(2) When a high voltage is applied to the vacuum chamber and ionized argon or the like hits the film-forming material at high speed,

(3) the atom of the material pops out from there and reaches the substrate to grow a thin film and form a film. Is completed.

This film forming material is called a sputtering target. The characteristics of the thin film change depending on the target used, and the film composition of alloys and composite oxides is maintained at almost the same composition as the target, so it is important to select the target according to the needs. Sputtering targets are not only single metals and alloys such as aluminum and copper, but also oxides such as TiO 2 , MgO, Al 2 O 3 , Nb 2 O 5 , InGaZnO 4 (IGZO), Pb (Zr, Ti) O 3 (PZT ). A wide range of materials such as composite oxides such as TiC and SiC and carbides such as TiC and SiC are used.

As a method for manufacturing a sputtering target, a sintering method is used in which raw material powder is heated at a temperature below the melting point to solidify the powder. , There is a melting method in which raw materials are melted and molded. Oxides with a high melting point are generally manufactured by a sputtering method, and metals and alloys with a low melting point are generally manufactured by a melting method. When installing a target in a vacuum chamber, Since a copper plate (backing plate) is often used for cooling, bonding between the target and the copper plate is also usually performed.

The higher the density of the sputtering target, the slower the film formation speed. , The target itself is fragile and easily chipped. When using a fragile target, it can be replaced by making it into a split tile shape and attaching it to the backing plate instead of one large size. Be careful about the arching of the split part.

◇ List of products and services

Toshima Manufacturing Co., Ltd. Materials Systems Division provides various materials for sputtering targets and thin films, from prototypes for R & D to mass-produced products, according to customer needs. We design and manufacture materials one by one according to the customer's request, and consistently process them in-house to achieve short delivery times.

| Battery material | Energy device material | Advanced functional materials | Contract service |

|

◇ Lithium-ion battery material ◇ Solar cell / fuel cell material |

◇ Superconducting material ◇ Thermoelectric conversion material ◇ Photocatalyst / artificial photosynthesis material |

◇ Ferroelectric material ◇ MRAM / magnetic device material ◇ Optical system functional material |

◇ Contract film formation ◇ Contract coating ◇ Bonding / backing plate ◇ Contract analysis |

◇ List of elements handled

The blue part is the element we handle. You can see the details from the link of each element.

DOWNLOAD

Catalog Sputtering Target